KRA Shot Cleaning System

The proven alternative to soot blowers for safe cleaning without process steam.

Especially for biomass and refuse-derived fuel (RDF) combustion, waste incineration plants, and thermal oil systems.

Especially for biomass and refuse-derived fuel (RDF) combustion, waste incineration plants, and thermal oil systems.

The System:

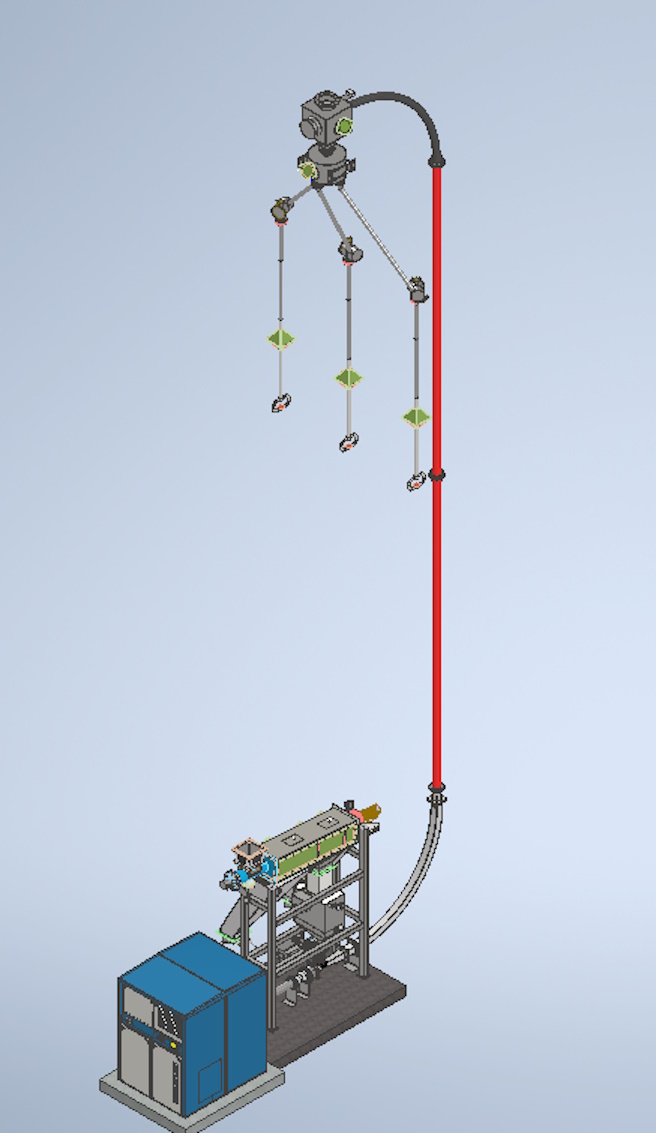

Our shot cleaning system is used for flue gas-side cleaning of heating surface tubes in waste and biomass-fired steam boilers, in the area of tube bundles in the superheater and economizer.

During operation, soft iron balls up to a maximum diameter of 8.0 mm are conveyed to the boiler ceiling by means of an air volume flow and then guided through the tube bundles of the boiler circuit. Below the flue gas funnel, the resulting ash/ball mixture is then separated in a sieve drum and the balls are returned to the cleaning cycle.

The shot cleaning principle is not suitable for empty circuits but is excellent for vertical flue gas circuits with horizontal superheater or economizer bundles. It also works well with non-aligned tube arrangements or larger bundle heights where other systems can no longer be used!

No additional media such as steam or compressed air are required.

The balls circulate in a gravity circulation principle, therefore IDEAL also for smaller plants or plants where the available amount of steam is limited.

Advantages of the Salzgitter KRA System:

• Safe and intensive cleaning, even of superheater heating surfaces

• Low space requirement! No lateral space reserve required, as with soot blowers

• No additional media requirement for process steam or compressed air

• Lower effort for piping and cabling compared to other cleaning systems

You can find more videos about our products here.